Vacuum-Packaging line for shrink bags reisacher XL-110T/ST-200

Ref: 903942

Automatic single chamber with an internal conveyor belt Automatic Shrink, electrically heated.

onsisting of:

Automatic single chamber with an internal conveyor belt.

Ideal in combination with the automatic shrink tank.

SPECIFICATION:

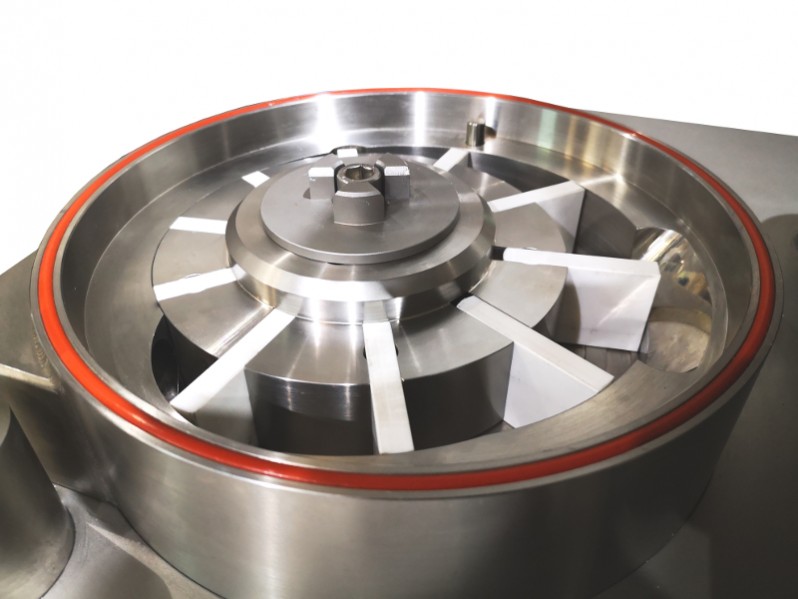

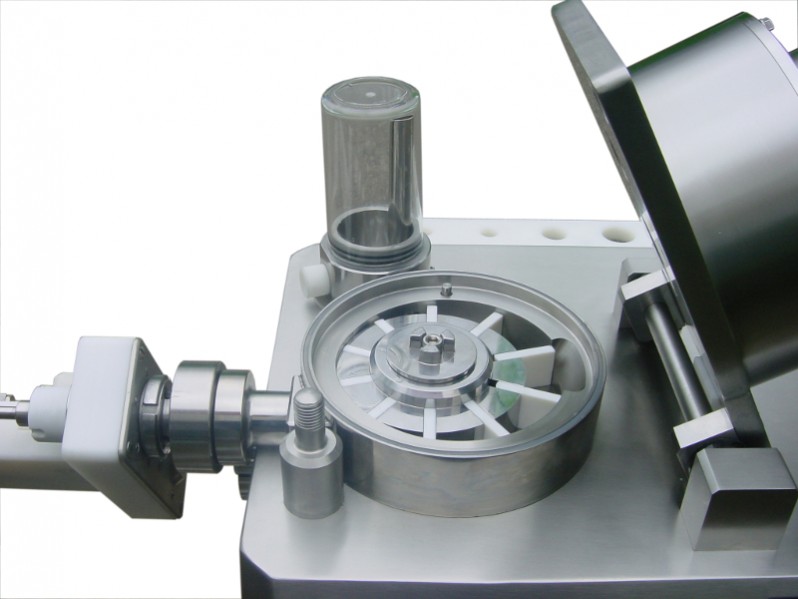

– Standard with 2 seal bars (front-left): 1,050 x 620 mm

– Standard double seal (two wires)

Optional without extra costs: cut-off or wide seal (10 mm)

– Silicone holders easily removable for cleaning and maintenance purposes

– Pump capacity: 160 m3/h Busch vacuum pump

– Pump maintenance and cleaning program

– Machine cycle: 15 – 45 sec.

– Standard ACS control with sensor and 20 program memory

– Soft Air to protect the product and vacuum bag

– Flat machine working plate

– Stainless steel housing

– IP-65 classification

– with integrated beld ejection

– Compressed Air consumption 100 Nl/min. 6 bar

OPTIONS:

– 1-2 Cut-off/Bi-active sealing

– 100 or 300 m3/h Busch pump

– Liquid control sensor

– Preparation for external pump

Automatic Shrink Tank

– Automatic platform with conveyor belt

– Digital temperature control

– Pneumatic movement

– Stainless steel housing

– Optimal hygiene

– Maximum loading capacity: 30 kg

– Machine dimensions: approx. 1,700 x 1,170 x 1,350 mm

(Length x Width x height)

– Chamber dimensions: 1,098 x 575 mm (Length x Width)

– Dip depth: 200 mm

– Dip time: 3-5 seconds

– Cycle time: 22 seconds

– Power: 23 kW

– Voltage: 400 Volt, 3-Phases, 50 Hz

– Compressed Air consumption 50 ltr./min, 6 bar

– Fully insulated

– Vapor exhaust ø125 mm, optionally equipped with built-in fan

– Water drain 2″

– Automatic water level control

– Built-in lime scale protection

– Weight: approx. 310 kg

Reviews

There are no reviews yet.