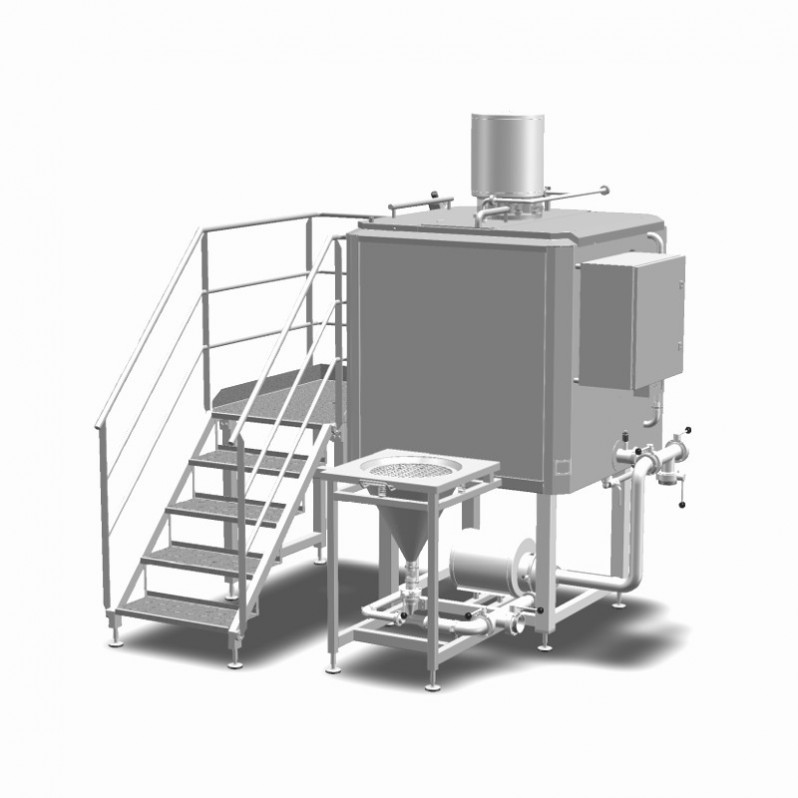

High Pressure Hydraulic Injector Mod. MP-60/2

The high pressure injection technology creates a multiple “spray” nebulizer effect, dispersed inside the muscle, which ensures optimal distribution of the brine, by obtaining a high injection with high production and providing great uniformity of color, flavor and texture. The multiple configuration possibilities of the different models allow productions of both a single product and different varieties with or without bone.

• Characteristics:

Strategically located injection points.

Adjustable injection percentage from 10 to 100% in a single pass.

Head with retractable needles and retainers.

Conveyor feed with electronically adjustable step.

Non-slip plastic modular belt conveyor.

Filtration of the brine through self-cleaning rotating drum, two plate filters and a suction filter.

Brine tank with agitator.

Needle connection through quick links by push buttons.

Transparent protections for visual control of the injection.

Hydraulic actuation of the cylinders.

Built in AISI-304 stainless steel and FDA technical plastics.

Control panel with programmable automaton and touch screen.

• Optional:

Reinforced blade-type tenderizer head set connected to the head.

Injection height increase to 250mm.

Injection system with electronically variable pressure.

Tank with double jacket for brine cooling.

- Production4000Kg max*

- Overall dimensions (LxWxH)3300x2400x2500mm

- Tape width470mm

- Injection height200mm

- Number of Heads / Number of Needles2/60

- Injection points660

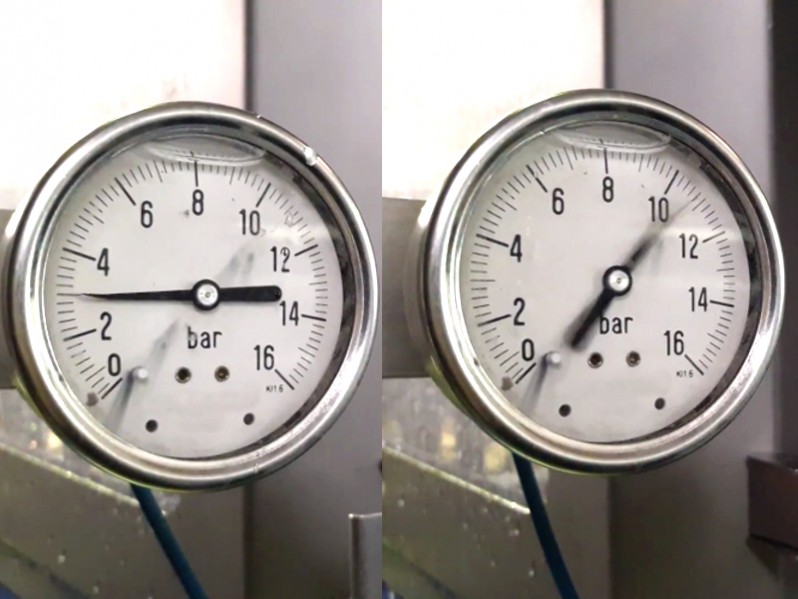

- Injection needle pressure6bar

- Maximum injection volume4L/cycle

- Conveyor feedfrom 15 to 100mm/cycle

- Electric power23,5kW

Reviews

There are no reviews yet.